Product Details

Product Introduction

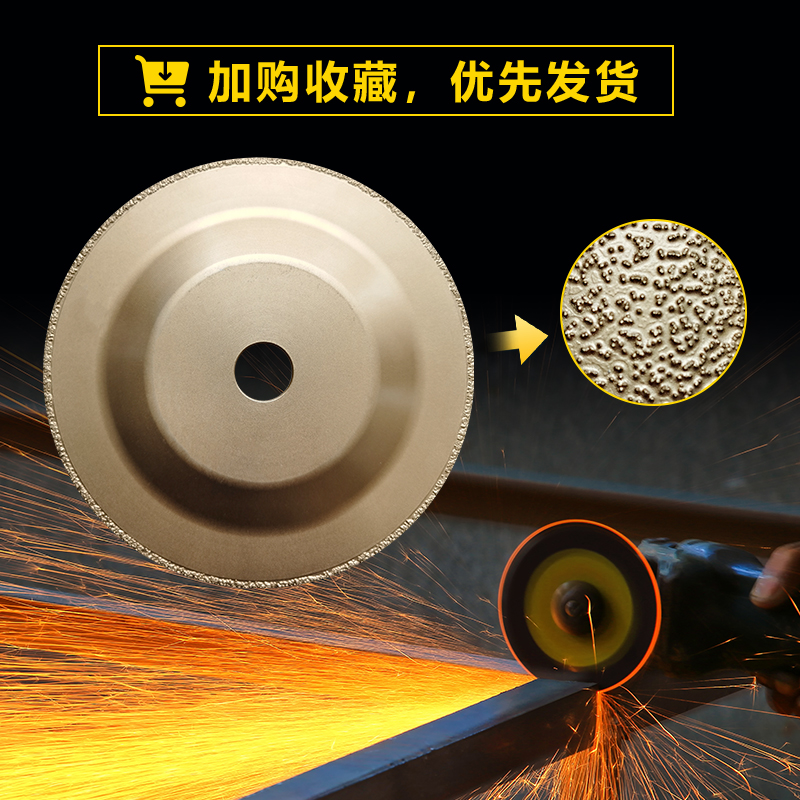

Henan Youde Superhard Tools Co., Ltd. independently develops custom brazed diamond grinding cup wheels, utilizing advanced brazing technology combined with high-quality diamond particles for exceptional grinding efficiency and superior wear resistance. Available in diameters ranging from 100 to 180 mm, these wheels support a wide range of flat and curved surfaces to meet diverse machining needs. Their durable and impact-resistant design ensures excellent performance in the precision machining of a variety of metal and non-metallic materials, including gray iron, ductile iron, stainless steel, carbide, stone, ceramics, and glass. These wheels comply with international CE certification standards, are backed by multiple patents, and are fully monitored by our rigorous quality management system. We are committed to providing high-performance abrasive solutions to our global customers. Our professional after-sales team offers rapid response and customized technical support, helping customers maximize production efficiency in the face of fierce market competition.

Advantages and features

1. High-quality diamond particles combined with an advanced brazing process ensure efficient grinding and long-lasting durability. 2. Customizable sizes ranging from 100 to 180 mm are available to meet diverse processing needs. 3. The product structure is impact-resistant and equipped with safety features to ensure safe operation. 4. It is suitable for a wide range of metal and non-metal materials, including gray iron, ductile iron, stainless steel, ceramic, and glass. 5. CE certification and multiple patented technologies ensure product quality and international market competitiveness. 6. A strong after-sales service system provides rapid response and customized technical support, ensuring a worry-free customer experience.

Application Scenario

This product is widely used in heavy industrial manufacturing, mold processing, glass polishing, stone carving and carbide processing. It is suitable for customers such as mechanical processing plants, mold manufacturers, stone processing companies and glass product processing plants. It can meet the precision grinding needs of different materials and processing forms. It is an ideal choice for improving production efficiency and surface quality.