Product Details

Product Introduction

Henan UHD Superhard Materials Tools Co., Ltd. (UHD) meticulously develops vacuum-brazed diamond saw blades specifically designed for high-power automated cutting equipment. Utilizing advanced vacuum brazing technology, these blades ensure a tight bond between the diamond particles and the steel substrate, significantly extending blade life and reducing maintenance and replacement costs. The blades' custom-designed cutter head geometry is compatible with a wide range of automated cutting machines, optimizing cutting accuracy and smoothness for high-speed cutting of high-strength materials such as cast steel and cast iron. UHD strictly adheres to ISO 9001 quality management system standards and undergoes dynamic balancing tests to ensure the safety and reliability of each saw blade, making them suitable for industrial applications such as machinery manufacturing, metalworking, and casting cleaning. The company also provides comprehensive technical consulting and global after-sales support to help customers achieve both improved cutting efficiency and safety. Choose UHD vacuum-brazed diamond saw blades and experience the long-lasting durability and high-efficiency performance delivered by cutting-edge technology to safeguard your production line.

Advantages and features

1. Using high-quality vacuum brazing technology to achieve a firm bond between diamond particles and the matrix, extending the service life of the saw blade.

2. Customized cutter head geometry design, compatible with a variety of automatic cutting machines, improving cutting stability and accuracy.

3. High power support, efficient cutting of various cast steel and cast iron materials, significantly improving production efficiency.

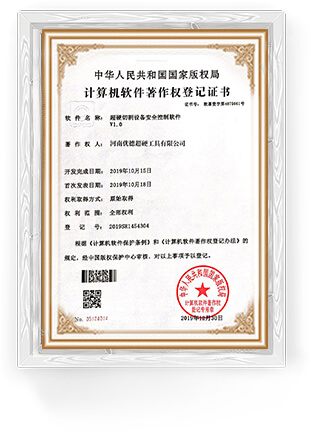

4. Strictly implement ISO 9001 quality management system, and the product has passed the dynamic balance test to ensure safe use.

5. Provide professional technical support and global after-sales service to meet multilingual and personalized needs.

6. Low maintenance cost, reduced downtime and improved overall processing efficiency.

Application Scenario

This product is widely used in the machinery manufacturing, metal processing, and foundry industries, particularly for high-speed automated cutting of high-strength materials such as cast steel and cast iron. It is suitable for industrial production lines, casting cleaning, mechanical parts processing, and automated cutting equipment. Target customers include foundries, large machinery manufacturers, and various metal industry clients, helping to improve production efficiency and reduce operating costs.